WHEN FLEXIBILITY IS THE PRIORITY

highest FLEXIBILITY

- complete change of metal grade with every ladle

especially for small BATCHES

- high performance where other systems are overkill

first step into AUTOMATION

- semi automatic pouring without big upfront costs

ABOUT

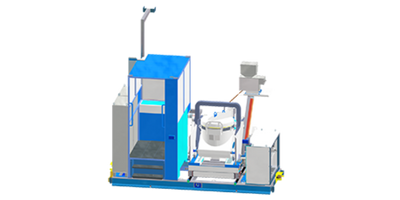

A saver production with increased speed: In addition to bottom pouring ladles and furnaces, we offer a much simpler tilt pouring system, which is perfect for pouring small batches on flask lines. Especially if the metal grade changes frequently, the tilt pouring system is the most convenient solution.

TECHNICAL INFORMATION

– Capacity: 1.000 – 5.000 kg

– Travel speed 100mm/sec.

– Hydraulic tilting

|

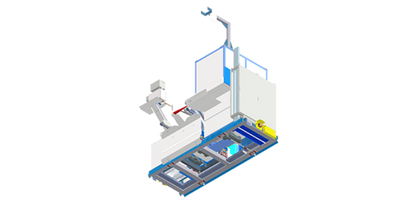

OPERATOR CABIN ON THE CARRIAGE– For optimal pouring conditions – Keeps the operator safe from iron – Main functions controllable from the carriage |

|

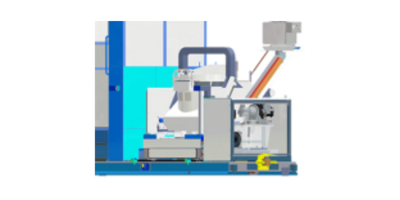

EASY POURING– Precise hydraulic tilting – Pivot point in the center of pouring stream |

|

COVERED LADLES– Reduce temperature losses – Keep the operators away from heat radiation |

|

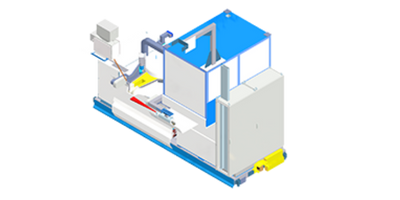

LONG AND CROSSTRAVEL– Carriage can move along the moldline – Pouring position can change for different models – Pouring stream can be adjusted to hit the mold at exactly the right spot |

|

MOLDLINE SYNCHRONISATION– Carriage can be synchronised to the moldline movements – Pouring can continue during indexing of the moldline |

|

SAFETY– Equipped with sensors scanning the surroundings – People are safe to walk around the carriage without the danger of getting hit |