FerroECOBlast is a leading company in the surface finishing industry, specializing in custom-made solutions and production machinery. We are renowned for our expertise in abrasive blasting, foundry automation, and foundry industry solutions. Our wide range of foundry machinery ensures optimal surface preparation and treatment for components in the foundry industry.

Foundry Industry Solutions for Perfect Surface Preparation

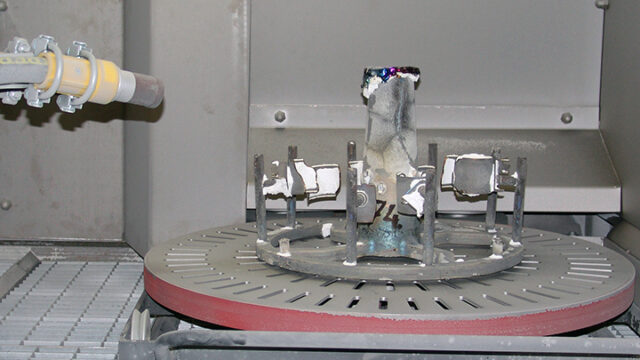

Our solutions for the foundry industry include precise and controlled abrasive blasting and deburring, ensuring a uniform and fine surface finish. We also specialize in the automation of blasting and cleaning processes, streamlining operations, and enhancing efficiency. Additionally, we offer advanced solutions for cleaning molds using the Dry Ice blasting process. With our equipment, you can achieve optimal cleaning results and evaluate the effectiveness of the blasting and cleaning processes.

Check our Foundry Solution Videos

Manual, Automatic & Robotic Air Blasting

Laser Cleaning, Marking

Dry Ice & Dry Snow Cleaning

UHP Water Jetting

|

|

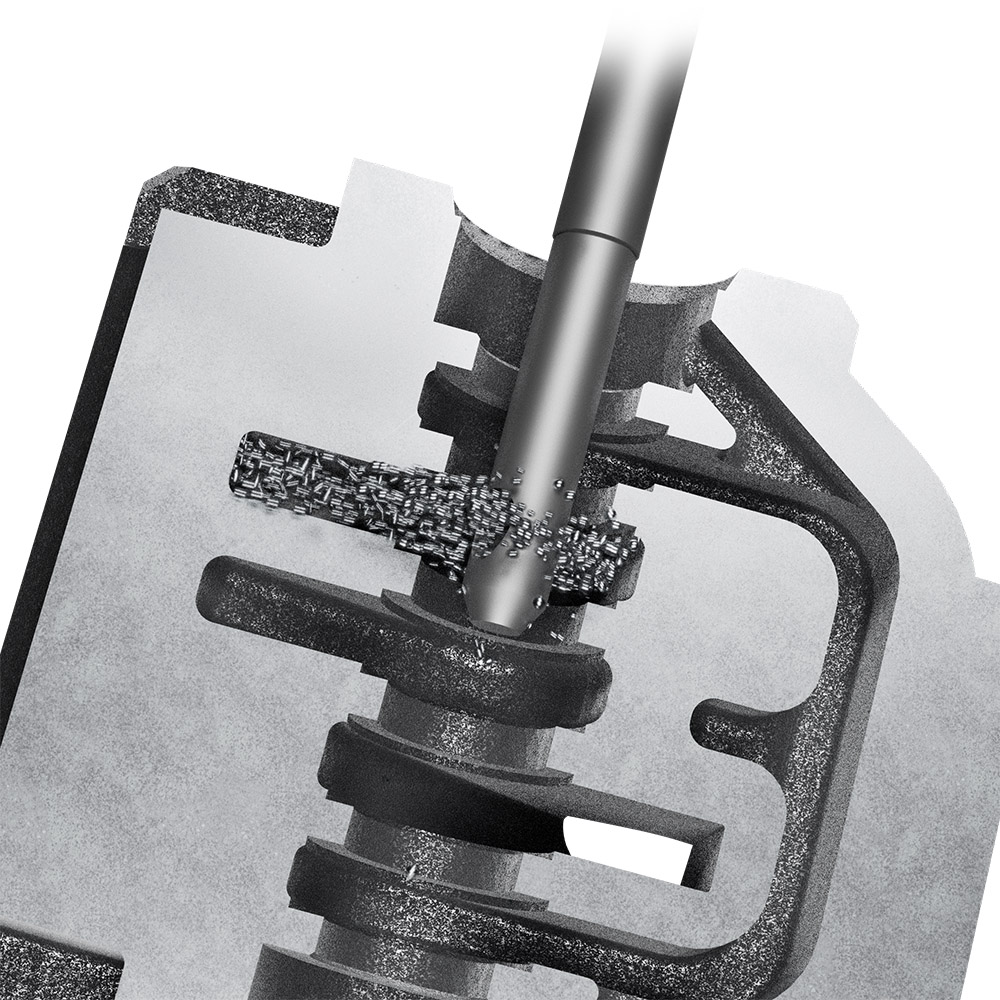

What Sets Us Apart?In our company, we are continuously dealing with the problem of deburring sensitive parts. As you all know very well these imperfections are the results of the technological process. Today we have the technical requirements for near-perfect products since such imperfections can cause undesirable effects. Short-term and long-term effects. Just imagine these inappropriate not so perfect parts to be installed in the safety systems of the vehicles you use every day to drive your children to school. Our mission here is to remove these imperfections on this sensitive but precise casting (for example made of ZAMAC alloy) and in the end not to damage them. |

|