AUTOMATIC POURING & HIGH QUALITY TECHNOLOGY FOR EVERY IRON FOUNDRY

The pourTECH™ system is the result of years of customer feedback, research and continuous improvement. This is where technology, software development and mechanical engineering come together. Our pouring systems are equiped with lasers and cameras to ensure high levels of automation. We find innovative solutions to your practical challenges in cast processes. From a hardly automated system to a highly developed end-to-end automated solution. The pourTECH™ system offers a high degree of flexibility and a wide range of customization options.

AUTOMATION

LEVELS OF AUTOMATION |

|

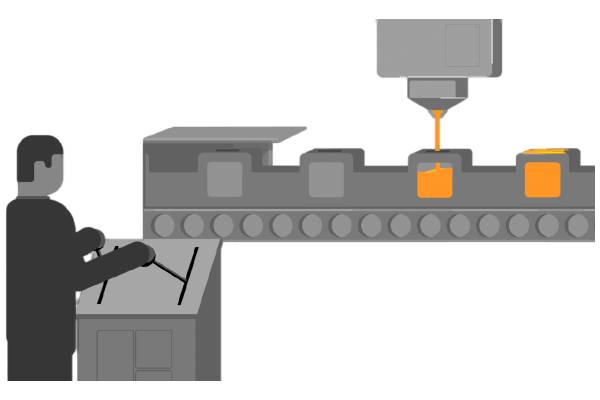

MANUAL POURINGThe system is controlled manually by an operator and is built with the possibility to upgrade to a semi- or full automatic pouring system. |

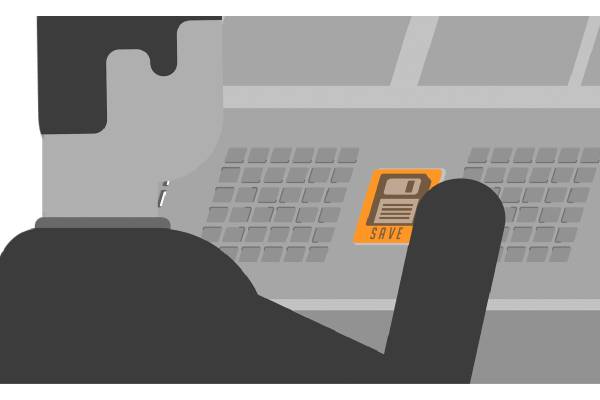

SEMI-AUTOMATIC POURINGTeach-In mode: The pouring will be recorded on basis of manual pouring. The next molds are poured by repeating function. |

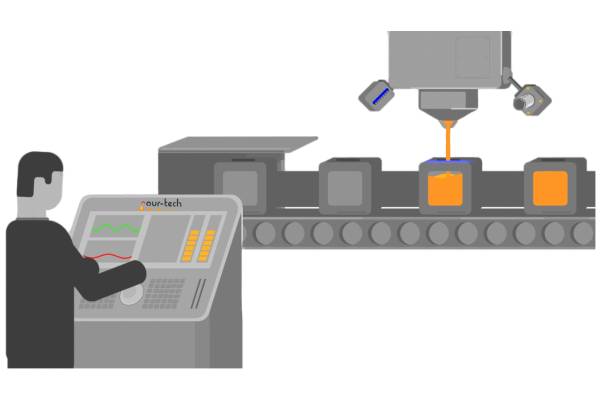

AUTOMATIC POURINGThe operator is released from the basic setup – only adjustments are needed. This level offers a wide range of functional tools. |

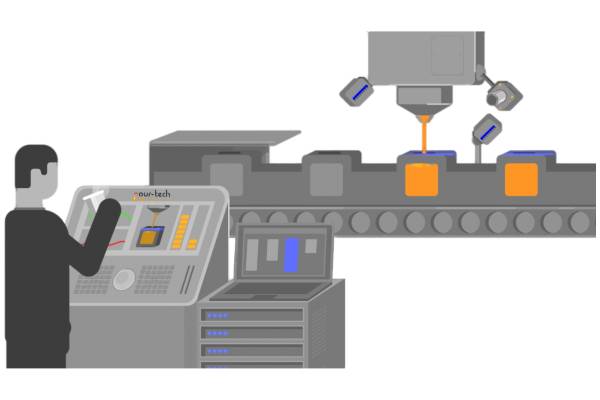

INTELLIGENT POURINGThe system is enhanced by artificial intelligence. It controls and optimizes the pouring cycle by itself and communicates with the mold line. For the process itself, the operator is not needed anymore. |

PRODUCT PORTFOLIO

POURING SYSTEMS

UNHEATED BOTTOM POURING LADLEThe system is designed for fast iron grade changes and offer reduced temperature and fading losses. |

TILT LADLEThe system is perfect for pouring small batches on flask lines. Especially made for frequent metal grade changes. |

CORELESS POURING FURNACEThe patented elliptical coil allows for easy maintenance, high uptime and constant pouring temperatures. |

CHANNEL POURING FURNACEFor profitable, high quality castings in grey iron foundries |