SIMPLE & UPGRADABLE DESIGN

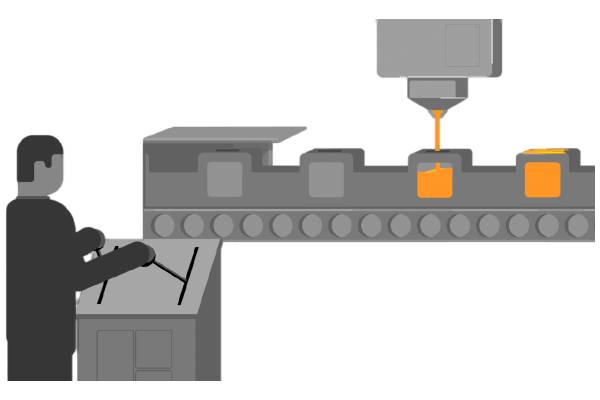

The manual pourTECH™ system is equipped with hydraulic stopper rod actuator unit including necessary hydraulic, pneumatic, and hardware systems. It operates on horizontal and vertical mold lines, and will perform as follows:

- Operator controls the flow of molten metal from the nozzle into the mold by opening and closing the stopper.

- Opertator will position the pouring unit with the nozzle over the pouring cup.

- By joystick, he will open and close the stopper manually.

In case of Mg-treated iron a pneumatic driven stopper twist and plunger can be supplied.

PROFIT FROM MANUAL POURING

Simple design

- For your individual requirements constructed.

Plug & play installation

- pour-tech engineers are not needed for installation and start-up.

Possibility to upgrade

- For a higher level of automation the system is designed to accommodate additional needed sensors and equipment.