THE HIGH-END SOLUTION FOR A SELF-LEARNING PRODUCTION

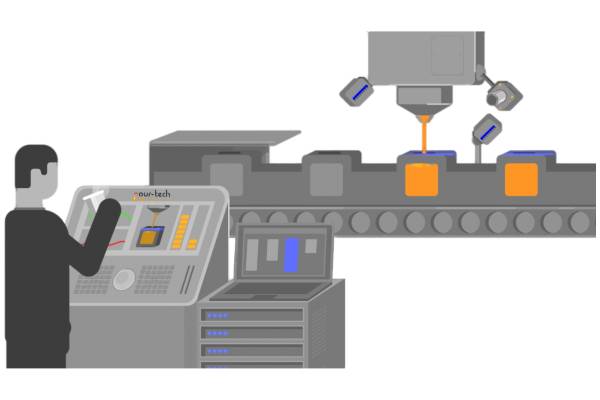

The intelligent pourTECH™ system is equipped with an electric servo drive stopper rod actuator unit, hydraulic, pneumatic, hardware and control systems.

The system operates on horizontal and vertical mold lines, and will perform as follows:

- The PLC controls the flow of molten metal from the nozzle into the mold by opening and closing the stopper. It gets information by the laser to be able to adjust the filling speed. Using the specific parameter stored in a database, the pouring will be performed for each individual pattern.

- Control System is enhanced by artificial intelligence called EASYpour™.

- EASYpour™ controls and optimizes the pouring cycle by itself and communicates with the mold line. For the process itself, the operator is not needed anymore.

- The PLC will position the pouring unit with the nozzle over the pouring cup by a dedicated laser control system.

In case of Mg-treated iron a pneumatic driven stopper twist and plunger can be supplied.

PROFIT FROM AUTOMATIC POURING

No adjustments needed

- EASYpour™ is a self tuning system and the needed adjustemts are not necessary any more.

Selflearning process

- Feed back for each mold can be stored in database Due to the working with AI, the process will be improved anytime.

High relief for the operator

- Operators are completely released from the repeatable work. They can do some other work during the pouring or take a break.

Quality improvement

- By having constant pouring conditions the quality will be improved and the scrap rate can be reduced.

Profitable production

- Higher output of the foundry due to higher yield.

|

EASYPOUR™NO NEED TO OBSERVE THE POURING PROCESS BY AN OPERATOR It is complicated getting skilled operators for one of the most important processes in the foundry – the pouring of molds. Therefore we developed a digital operator supported by artificial intelligence called EASYpour™. The technology is based on self-learning algorithms which monitor the current state of the pourTECH™ system together with historical data from the pourTECH™ database. EASYpour™ controls the pouring parameters to continuously optimize the pouring and trying to maintain a high and consistent result of the pouring. For each pour, EASYpour™ will try to make the next one better or at least as good as the previous one, this enables a very high consistency in the production. |

INOTECH™INOCULATION DETECTION REDUCE INOCULATION MATERIAL AND DEFECTS The inoTECH™ in stream inoculation detection system gives the operator the full control over the inoculation process. By using the pour-tech inoculation it detects the actual hit rate of the inoculation material into the iron stream. A blue line laser illuminates the area of the pouring stream and creates a laser curtain. A vision camera is installed in line with the inoculation tube. When the material is leaving the tube, it must go through the laser curtain and creates flashes, which are detected and counted by the camera. inoTECH™ determines the actual hit rate with this information. The allowed tolerances can be set in the parameters. If not enough material hits the stream, the system generates an alarm, and the production will be stopped until the problem is solved. |

|

|

MOLD MAPPINGFULL CONTROL THE WHOLE POURING PROCESS The mold mapping function provides monitoring of all molds currently existing along the mold line, from mold machine to shake out. Each mold is linked with information such as pouring pattern number, pouring result, pouring time, final level and iron batch. Additional information from external machines/devices can also be linked, if available. This can be for example the mold number, pour box level, mold thickness and iron temperature |